Insulating electrical conductors in discrete circuits has been a necessary process since the inception of electricity. Many studies, developments and innovations in the wire industry have been made regarding thickness, physical characteristics, insulation material types — all with one goal. Safely and effectively insulating the electrical conductors carrying power. Using Heatshrink There are many implications for heatshrink tubing from safety and physcial reinforcement to identifying wire ends. Safety When a wire is stripped to reveal its inside conductors for crimping, soldering or connecting to an electrical system, there is often a need to re-cover the copper to protect the circuit …

Aligning Quality Systems For Critical Traceability Of Military and Medical Applications

…They employ advanced tracking/reporting systems and requirements in order to make all parts and components being used in their products traceable….

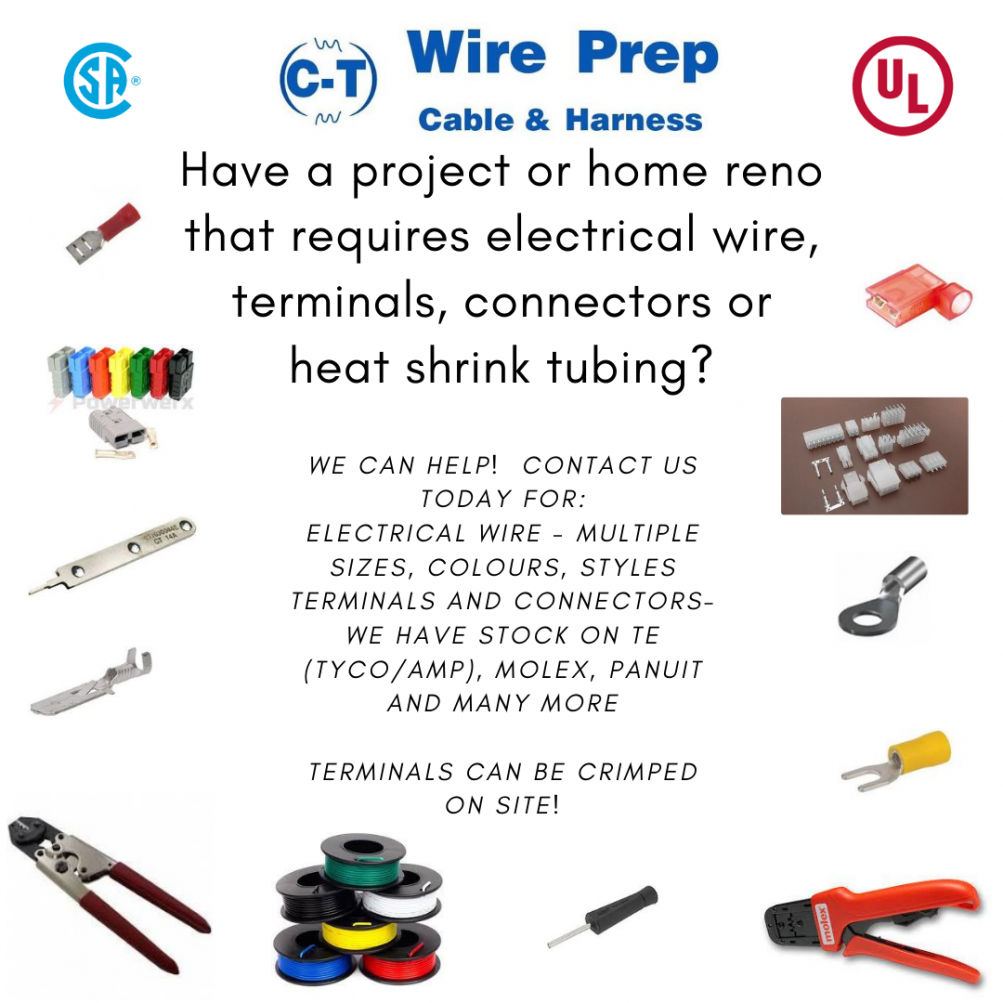

Contact Us For Component Stock and Custom Wire Solutions

A little known fact about applying terminals to a wire tip is the quality difference between application with hand tools compared to using a 2 ton press designed for such a process. The speed and exacting crimp depth (measured crimp height after application) reached by a professional grade press creates a gas tight, corrosion resistant bonding between the copper wire strands and the terminal within the barrel of the wire crimp. There is a profound difference when destructive pull-testing is used to test the strength of the connections between the two application methods. Connections applied by hand using a hand …

- Page 2 of 2

- 1

- 2