Knowing what the markings mean on registered wire gives you an advantage when dealing with any electrical system.

The characteristic information printed on the wire provides a ton of detail about the circuit it is connected to, as well as providing traceability through the supply chain for where the wire came from. These markings define what the wire can be used for, its physical limitations like fire ratings, pliability, compositions, registered file numbers for wire use, wire gauge and more!

A telltale sign that you are purchasing registered, high quality wire is that is will always come with printed markings.

Let’s have a look at a few markings commonly seen on wire to understand how it reads and how you can check your own wire products for legitamacy.

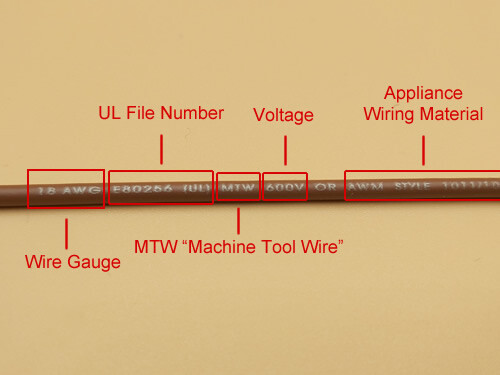

Standard Wire Markings:

Wire Gauge: This part is pretty self-explanatory, describes the conductor thickness in standard American Wire Gauge

UL file Number: This describes the company who is registered with UL to manufacture this specific run of wire

MTW: Stands for “Machine Tool Wire” and is a designation by UL on what the application of this product is for

Voltage: This is the rated voltage standard from UL which is determined by insulation wall thickness and wire conductor gauge

AWM Style…: This designation defines another application for wiring appliances that this wire is rated for. Special ratings were developed as a result of household fires due to appliance wire melting

1000v: This is the voltage designated for using this wire in an appliance

So you can start to see the importance of having these rated features on wire.

Many products being created today for the consumer electronics industry from unregulated manufacturing environments like china are using non rated wire. This poses issues with standards for safety domestically.

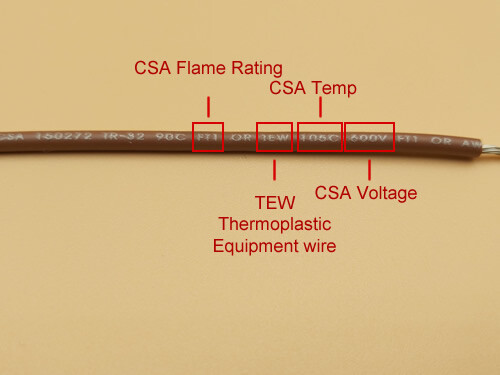

Here are some more labels you can see that show CSA ratings inline with the others on the same wire.

This wire is dual rated for use in both UL and CSA applications (CSA in Canada and UL in the USA) But can be tested and designated by either in todays industry.

VW-1: This is a designation by UL for vertical flame retardance and means that this wire has been tested to UL858 standards

CSA xxxxxx: This label describes the manufacturer of this specific run of wire by CSA

TR-32: This is a CSA designation of wire type similar to MTW or AWM and describes a standard of high voltage TEW hookup wire

90c: This is the temperature rating as standardized by CSA

You will notice similarities between the UL standards and CSA, but products require very specific designations for each country separately.

FT1: This flame test rating is CSA’s equivalent test to UL’s VW-1 rating. This standard applies a torch to a vertical wire 5 times for a specified length of time and the wire must withstand it and extinguish within 60 seconds to pass

TEW: Stands for Thermoplastic Equipment Wire and is the CSA equivalent to UL MTW for use on machinery

105c: Similar to UL 90c, CSA rates this wire slightly higher in temperature tolerance than UL. This disparity tends to happen when different certification bodies use different voltages to test wires

600v: This voltage rating is by CSA and defines safe use for machinery

All end user products in North America should have been tested and have CSA or UL designations to comply with safety standards.

At C-T Wire Prep Inc. we use dual rated wire in nearly all custom wire harness builds and definitely all leads. This ensures that no matter which market our products end up in around the world, they will comply with the regulations for that region and perform safely to each standard.

Part of the incoming QA process at the factory requires checking every barrel and spool that enters the facility for its designations and reporting that data along with our assemblies to provide traceability throughout the mfg process.

Visit the new <a href=”https://store.ctwireprep.com”>C-T Wire Prep Online Store</a> for discount certified components!

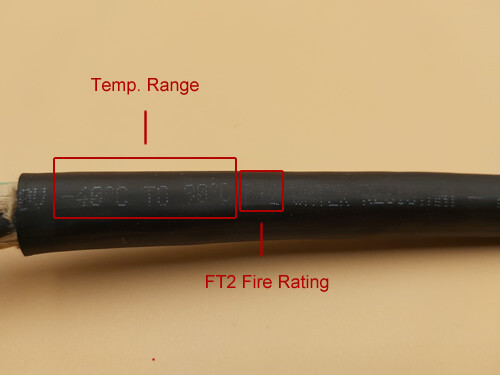

Cable Markings:

Temp Range: Due to the fact that many multi-core cables are used to provide outdoor power, cables come with a temperature range including a minimum operating temperature for use in cold climates

FT2: Cables are fire tested in a different way than single core wires because of their applications and physical makeup. It makes more sense that a flame would attack a multicore cable from the side as they are usually run parallel to the ground whereas, equipment wire is often routed vertically along machine walls. FT2 testing chars a cable for 30 seconds and the cable must not burn more than 100mm wide and must not drop molten plastics

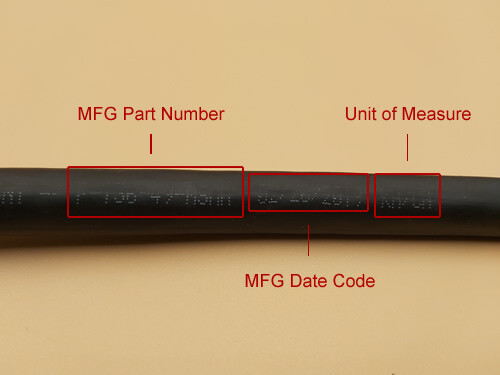

MFG P/N: A cable is considered a complete part once the cores are added and the jacket sealed around the internal cores compared to a single wire which is always a component of another product. Thus it can be named as a part to itself

Date Code: Not seen as often on the physical marking of wire and cable, but it helps provide enhanced traceability of raw goods used in products as a known date would help an investigator source the affected lot codes should there be a recall on products

Unit of Measure: Another feature not seen as often on all wire and cable, some manufacturers provide markings along the wire lengths to show their footage or meterage visually. This can assist assemblers with cutting to length, or tracking of wire length for inventory purposes

As always, we hope this article has been very informative and educational to you, and never hesitate to contact us if you have questions regarding any content!