We are living in an age where exponential technological increases are happening almost daily. As time goes on, technology continues to advance with 5g radio deployment, and more and more networked smart devices are coming online. It is an exciting, but scary time as people scramble to increase their personal knowledge levels to stay ahead of the next new thing. As a long-term manufacturing service in the electronics industry, we must do the same by looking into the future to see what it may hold for our industry and planning accordingly.

Power As A necessity

You are likely seeing the result of power technology advancement in the retail markets with inductive “Wireless” charging docks and other innovative solutions for powering devices like motion, solar and even static! These devices mark a certain stage of advancement in this industry that has been working on the same problem for many years.

Electricity is inherently a dangerous object. There are many standards, rules, processes and limitations regulated by authorities worldwide for its safe use to keep humans safe from electrical shock, injury and death. It has always been known that if you tried to make voltage wireless, it would become dangerous again by leaving its protective insulation sheathing that aims to separate it from human touch. So this area of study was always and is still approached with extreme caution where a race to new technology in this area is all but mute.

There is one common property that all of these “wireless” devices still share with the exception of solar power. They all still connect to WIRE in order to be powered so they can wirelessly power another object. You see, even in wireless, we still need wired power.

How Power Technology Advanced

So we’ve concluded that wire will still be needed well into the future of technological advancement to power wireless device land-tie points. Let’s look at how wire has been used in the past to make devices come alive, and how that paradigm is changing as technology advances into the future.

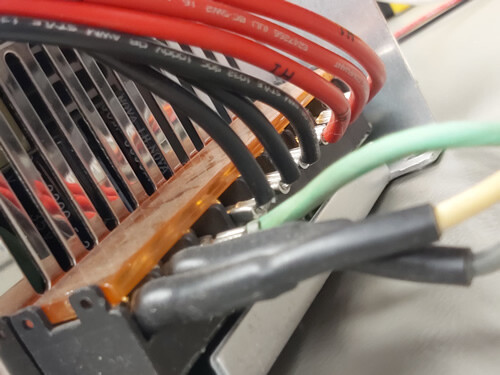

We are currently witnessing a shift in the use of wire for electronic devices where discrete wiring for data and low voltage use is shifting from single conductor copper core MTW style wire, to an “Automation” style multicable that can be produced much cheaper, and run multiple circuits simultaneously. Engineer’s practices used to include this fly-by-wire method of wiring for sensors, data links, control boards etc but today it makes more sense to use more complex cabling for these uses.

If we take a step back and look back to analog electronics for a minute, we find that this old type of wiring was a necessity in older machines and devices because analog circuits were driven by voltage which takes a high quality wire connection to happen successfully. High quality crimped terminal contacts must be made to keep vital circuit resistances in check for proper operation.

As time progressed, we saw the technological advancement to a CPU delivering instructions digitally to analog devices like relays for switching and instead of analog powered modules with lots of wires to make them work, we now see simple low power devices that handle the same processes. The need for low resistance crimped connections throughout a device is nearly absent for newer digital devices due to this.

A Look Into The Future

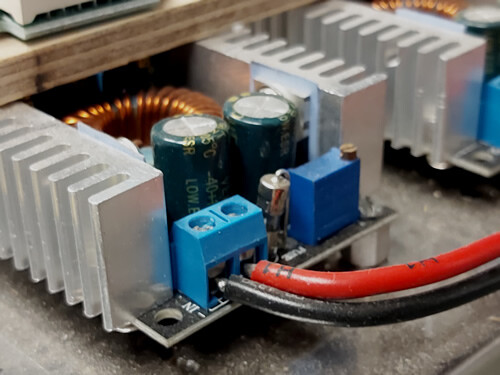

Power Supply is the main area of focus for the certified wire industry. The entry of electricity into a device whether 5g, wired or wireless or what have you, needs to be achieved safely. Into the foreseeable future, high quality certified wire will still be needed to power all electronic devices but their use is limited to the power supply section and any other analog power devices requiring high quality crimps that do not heat up under regular load. Otherwise, data and comm. connections are taken care of via multi-core automation data cabling.

We are also seeing more use of fusion welding techniques being used as high voltage electric vehicles come online. This is becoming a necessary technology in the EV market due to the same reason stated above about low resistance power transfer. With instant delivery batteries and high amperage draw electric motors in the cars, the demand for power has new challenges. Before electric vehicles, the focus in electronic product design was on voltage supply. This means designing a system to use enough voltage to carry out the electrical tasks it does. Today, the focus has shifted from how much power needs delivering to how FAST it must be delivered.

When you draw energy from a storage device (motor draws from battery), the harder or faster you draw it, the hotter it gets or the more stress is placed on the entire system. Heat creates electrical resistance in metals. In order to provide this level of power constantly, wired power systems must do so without failing due to heat.

New designs are removing the crimped contacts that the industry has always used for power, and replacing it with fused contacts that are made of the same copper as the wire. Fusion welding creates a guaranteed bond between the metals so there is no resistance created no matter how much energy you drive through the wire. Although certified F crimp power contacts aim to have the same characteristics of bonding via high speed/pressure application, they do not meet the requirements posed by the EV market and technologies.

Read about certified connections and their importance here

At this point in time, many devices still use the old fly-by-wire method for internal power distribution to their modules. There is much innovation that will take place over time in this area, but it must be done in a way that maintains the same quality level.

When you transition a device from analog to digital, there is the possibility of error introduction. The best part about the fly-by-wire method has always been its rock solid reliability. This is why the transition to digital versions has been so slow. Nothing beats the quality levels of the wiring method, but it is too costly to be used for the future.

Digital Devices must be error checked, tested and re-tested once digital to make sure it performs equally well as its analog counterpart long-term.

Over the next decade, we should see most devices successfully transitioned to digital versions as the world clamps down on the environmental use of resources, and aims to make technology smarter, smaller, and faster.

We hope you have found this article informative, interesting and engaging! If you believe this information is useful to others, please share below!