Purchasers and buying agents for electronic product corporations need the secrets – the inside scoop on sourcing vital wire and cable supplies and who to steer clear of

The Role Of Wire Harnesses In The Future Of Electronics

best part about the fly-by-wire method has always been its rock solid reliability. This is why the transition to digital versions has been so slow. Nothing beats the quality levels of the wiring method, but it is too costly to be used for the future…

Electronics Supplier Relationship Management: How To Acquire New Suppliers

Many electronic components are used for military applications and other restricted satellite and radio frequency uses, and require authorizations to purchase, export/import and even posess/use. Any credit app has some basic information that you should always

Electronic Components Shortages: Worldwide Effects Of The Pandemic

One way to fight against this inflation is to procure early in order to maintain price for your customers longer. It is inevitable that there will be increases over time, but we can at least help the situation by holding stock for longer that we know will be used by our faithful clients. This adds risk to manufacturing, so there needs to be some commitment from the customer side as well to limit that risk as far as promises to continue buying for the lifecycle of the product.

Quotations: The Basic Requirements For Successful CSA & UL Certified Electrical Cables and Harnesses

It is a known fallacy that different countries around the world use different limits, certifications and safety devices on electrical products that may or may not be legal and certifiable in other regions such as North America where advanced auditing, safety protocols and devices have been created as a result of dangerous products being audited and made safe.

Other certifications sometimes contrast with CSA and UL requirements so machines and devices adhering to other markets need to be readdressed when that product enters the North American Market.

Why Are M12 Cables So Famous?

Selecting the right M12 cable for your application is key to keeping costs down, and producing a product with a long lifespan. Engineers must analyze the movement of a machine and how the cabling is affected by it during operation to determine the correct jacketing flex combined with the right stranding to ensure performance …

Being An Environmentally Transparent Manufacturer In Today’s Economy

Let’s face it, planet earth is all we have and it is our job collectively as humanity to take care of it. Each member of society has a responsibility role to play and in business there is no exception to the rule.

Realizing Value: The Quality Implications Of Using Certified Electronic Components

There are huge cost differences between certified and non-certified components which needs to be considered when engineering a new product

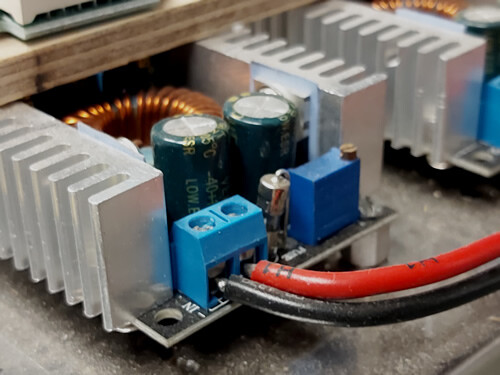

Best Practices For Wire Harness Assembly: Routing And Securing Wires

Once a product is known well enough and starts selling in the market, there is an opportunity for creators to save on cost, produce faster, and enhance the quality of the wiring aspects of the product by having an OEM supplier who specializes in wire harnesses help manufacture the product.

Incredibly Useful Manufacturing Process Design Tips For All Businesses

In order for manufacturers to maintain profit margins, scalability and repeatability in their processes, critical planning of all the necessary physical components is needed to execute a successful product launch with a client

- Page 1 of 2

- 1

- 2