Purchasers and buying agents for electronic product corporations need the secrets – the inside scoop on sourcing vital wire and cable supplies and who to steer clear of

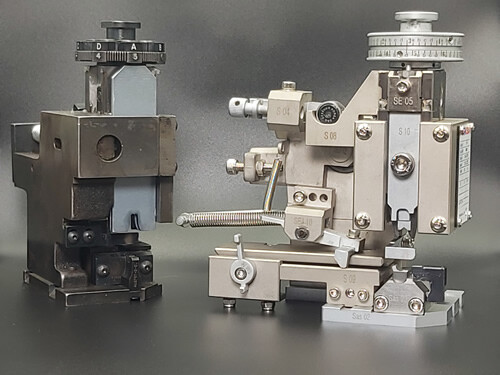

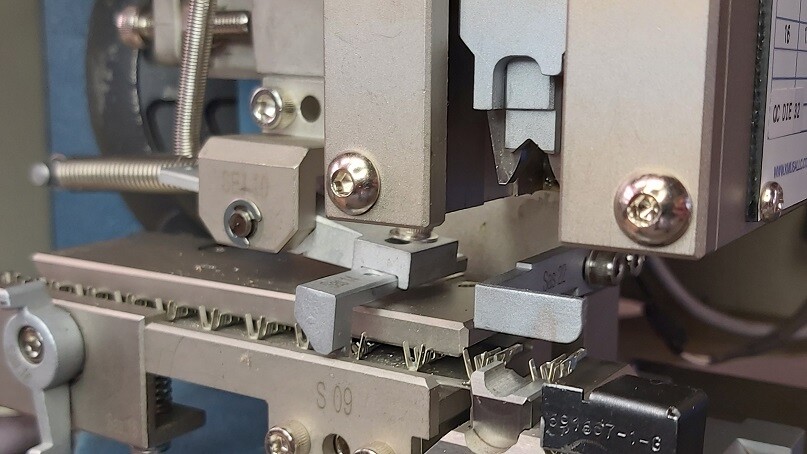

Semi-Automation: High Quality Crimp Tooling For Calculated Results

One of the main challenges that engineers face in the custom wire harness industry is the multitude of different connection systems available on the market. There are literally thousands of different types of connectors and their respective terminals will only fit the matching housings. This poses “pressing” questions (no pun intended!) 1. Which types do any given professional wire harness manufacturing facility have tooling for? 2. Which type are the best? 3. Most cost effective? Part of our job at C-T Wire Prep is to first educate engineering teams responsible for sourcing connection systems for their new products about availability …

Crimp Tooling Choices That Produce High Quality Parts

One of the most important choices you will ever make when sourcing a manufacturing establishment that produces its own cable assemblies or wire harnesses is how they will crimp terminals onto the wires they need. Choosing wisely is based on advanced knowledge of the levels of quality that is achieved using each method available. Smaller companies that are starting out or even larger companies have no formal training in the detailed aspects of wire processing which involves crimping terminals onto wire ends. They usually lean towards the cheapest method. The cheaper method essentially is to use hand-tool type pliers. Below …