Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

How To Guarantee Harness Quality: Using Cirris Continuity Scanning

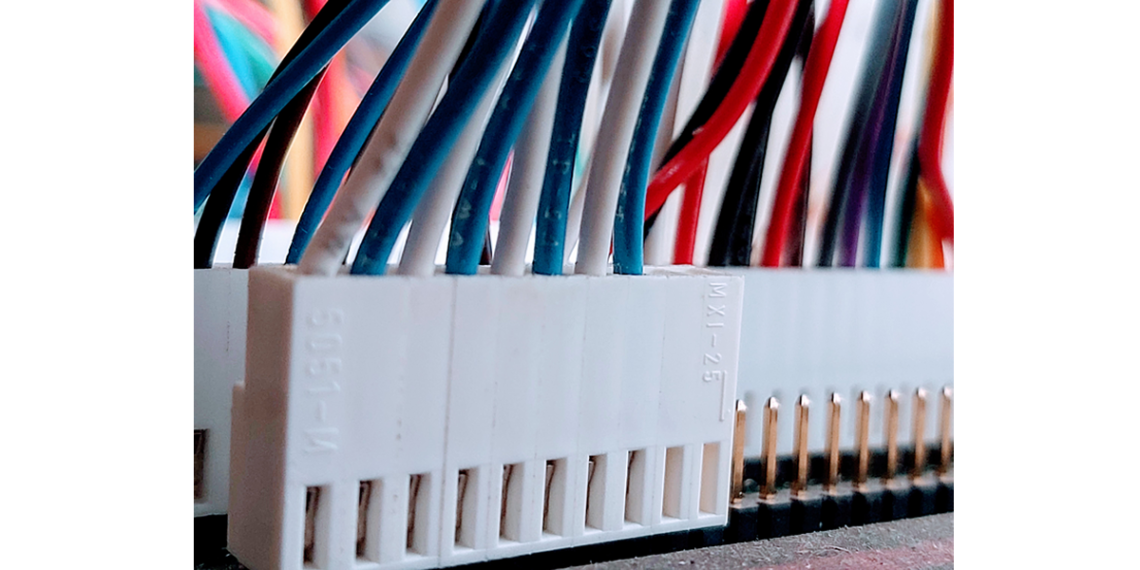

One of the main ways to ensure custom wire harness products are in perfect working order before they leave the facility is to test them against known limits electrically….Especially in low voltage data circuits, small discrepancies in resistance values can cripple digital sensing systems that require tight control of a circuit. As more delicate and complex digital robotic circuits become popular and standard, noise shielding failures can cause sensitive data circuits to be inaccurate resulting in machine failures and miscommunications. Cirrus testers can test these sensitive values repeatedly during assembly to maintain circuit integrity to a high degree.