best part about the fly-by-wire method has always been its rock solid reliability. This is why the transition to digital versions has been so slow. Nothing beats the quality levels of the wiring method, but it is too costly to be used for the future…

Electronic Components Shortages: Worldwide Effects Of The Pandemic

One way to fight against this inflation is to procure early in order to maintain price for your customers longer. It is inevitable that there will be increases over time, but we can at least help the situation by holding stock for longer that we know will be used by our faithful clients. This adds risk to manufacturing, so there needs to be some commitment from the customer side as well to limit that risk as far as promises to continue buying for the lifecycle of the product.

Get Expert Results: Outsourcing To Custom Wire Harness Manufacturers

It takes many years in business to curate a reliable vendor list for raw certified materials. Making orders for materials, seeing the products come in and their quality, lead time analyzation and volume cost breaks all must be top of mind as an outsourcing company to be able to provide a long service life for parts at the best prices.

Wire Cutting & Crimp Die Machine Setups: How To Limit Variability

Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

Wire To Wire Connections: How To Perform Commercial Grade Attachments

Electricity does not discriminated on connection quality and will pass voltage so long as there is a physical link of any size from wire to wire. This creates variability in the quality of various connections because of other factors created as a result of less than adequate connection.

Electrical Resistance and Heat are the two main failures created when a wire to wire connection is done wrong…

Quotations: The Basic Requirements For Successful CSA & UL Certified Electrical Cables and Harnesses

It is a known fallacy that different countries around the world use different limits, certifications and safety devices on electrical products that may or may not be legal and certifiable in other regions such as North America where advanced auditing, safety protocols and devices have been created as a result of dangerous products being audited and made safe.

Other certifications sometimes contrast with CSA and UL requirements so machines and devices adhering to other markets need to be readdressed when that product enters the North American Market.

Why Are M12 Cables So Famous?

Selecting the right M12 cable for your application is key to keeping costs down, and producing a product with a long lifespan. Engineers must analyze the movement of a machine and how the cabling is affected by it during operation to determine the correct jacketing flex combined with the right stranding to ensure performance …

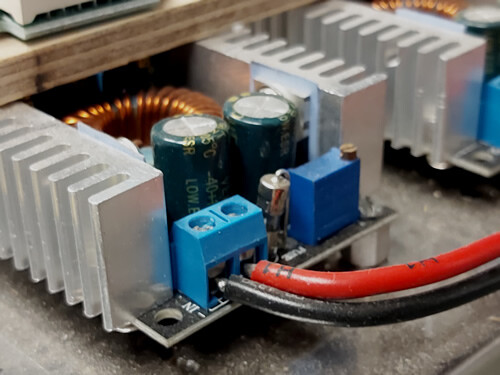

Realizing Value: The Quality Implications Of Using Certified Electronic Components

There are huge cost differences between certified and non-certified components which needs to be considered when engineering a new product

Wire Quality: Common Issues Found During Production

Wire mills around the world each manufacture wire with a variety of requirements and certifications governing their quality. In North America, you will most often see the markings of CSA and/or UL as well as markings specific to industries like automotive and aerospace such as SAE, CE, MIL-XXX etc. depending on application.

Every performance characteristic about a wire is defined within the certifications like maximum operating voltage, flame retardance and burn characteristics, temperature tolerances, insulation thicknesses, platings on conductors.

Best Practices For Wire Harness Assembly: Routing And Securing Wires

Once a product is known well enough and starts selling in the market, there is an opportunity for creators to save on cost, produce faster, and enhance the quality of the wiring aspects of the product by having an OEM supplier who specializes in wire harnesses help manufacture the product.

- Page 1 of 2

- 1

- 2