Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

Wire To Wire Connections: How To Perform Commercial Grade Attachments

Electricity does not discriminated on connection quality and will pass voltage so long as there is a physical link of any size from wire to wire. This creates variability in the quality of various connections because of other factors created as a result of less than adequate connection.

Electrical Resistance and Heat are the two main failures created when a wire to wire connection is done wrong…

Business Models Are Changing: Taking A more Calculated Approach

The idea of the digital transformation comes as a result of innovating the backbone systems controlling our online experiences. Algorithms dictate much of what we see, how we influence others through marketing, and our overall digital reach as businesses.

If we can learn to understand how these systems work for us, we can best use them for our benefit if we can transform how we do things to excite them.

There are some basic facts about how these algorithms function:

Quotations: The Basic Requirements For Successful CSA & UL Certified Electrical Cables and Harnesses

It is a known fallacy that different countries around the world use different limits, certifications and safety devices on electrical products that may or may not be legal and certifiable in other regions such as North America where advanced auditing, safety protocols and devices have been created as a result of dangerous products being audited and made safe.

Other certifications sometimes contrast with CSA and UL requirements so machines and devices adhering to other markets need to be readdressed when that product enters the North American Market.

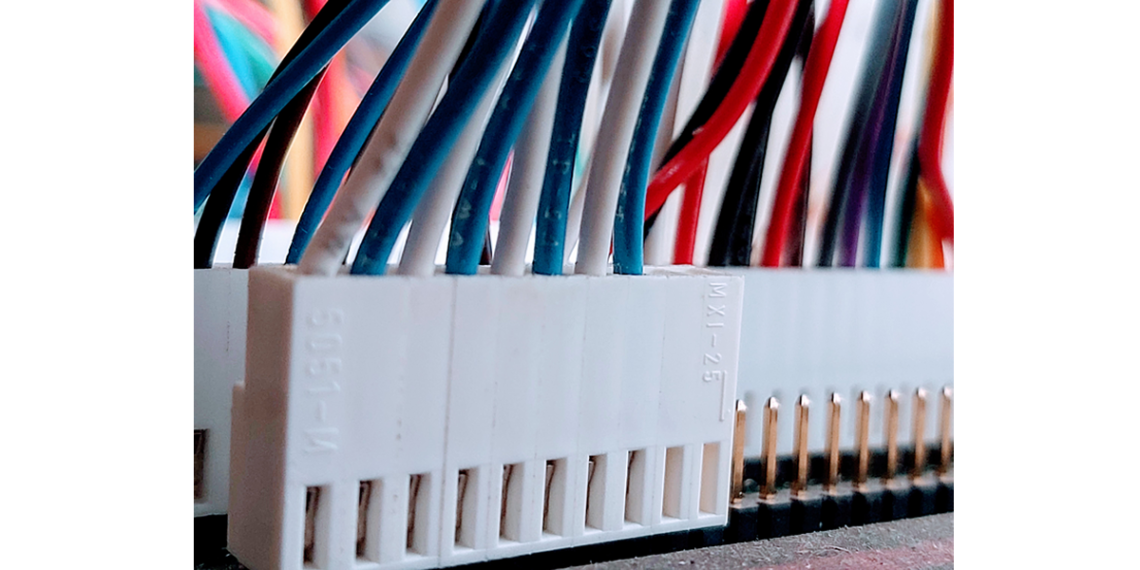

Best Practices For Wire Harness Assembly: Routing And Securing Wires

Once a product is known well enough and starts selling in the market, there is an opportunity for creators to save on cost, produce faster, and enhance the quality of the wiring aspects of the product by having an OEM supplier who specializes in wire harnesses help manufacture the product.

How To Guarantee Harness Quality: Using Cirris Continuity Scanning

One of the main ways to ensure custom wire harness products are in perfect working order before they leave the facility is to test them against known limits electrically….Especially in low voltage data circuits, small discrepancies in resistance values can cripple digital sensing systems that require tight control of a circuit. As more delicate and complex digital robotic circuits become popular and standard, noise shielding failures can cause sensitive data circuits to be inaccurate resulting in machine failures and miscommunications. Cirrus testers can test these sensitive values repeatedly during assembly to maintain circuit integrity to a high degree.

Incredibly Useful Manufacturing Process Design Tips For All Businesses

In order for manufacturers to maintain profit margins, scalability and repeatability in their processes, critical planning of all the necessary physical components is needed to execute a successful product launch with a client

Fundamentals Of Heatshrink – Discussing The Who, What, Where, When, Why & How

Insulating electrical conductors in discrete circuits has been a necessary process since the inception of electricity. Many studies, developments and innovations in the wire industry have been made regarding thickness, physical characteristics, insulation material types — all with one goal. Safely and effectively insulating the electrical conductors carrying power. Using Heatshrink There are many implications for heatshrink tubing from safety and physcial reinforcement to identifying wire ends. Safety When a wire is stripped to reveal its inside conductors for crimping, soldering or connecting to an electrical system, there is often a need to re-cover the copper to protect the circuit …

Custom Build Jigs: Design Techniques Used In The Wire Industry

When a new custom jig is designed, the designer takes into account every connection point possible on the harness in order to plan for integrating real-time high speed test scanning ability into the jig…