Purchasers and buying agents for electronic product corporations need the secrets – the inside scoop on sourcing vital wire and cable supplies and who to steer clear of

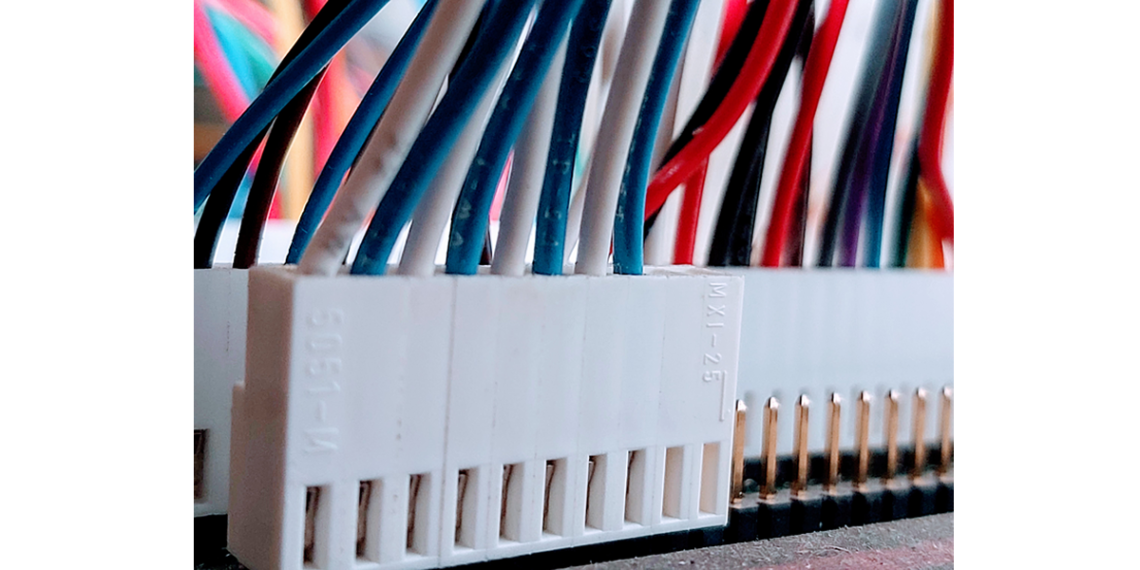

Best Practices For Wire Harness Assembly: Routing And Securing Wires

Once a product is known well enough and starts selling in the market, there is an opportunity for creators to save on cost, produce faster, and enhance the quality of the wiring aspects of the product by having an OEM supplier who specializes in wire harnesses help manufacture the product.

How To Guarantee Harness Quality: Using Cirris Continuity Scanning

One of the main ways to ensure custom wire harness products are in perfect working order before they leave the facility is to test them against known limits electrically….Especially in low voltage data circuits, small discrepancies in resistance values can cripple digital sensing systems that require tight control of a circuit. As more delicate and complex digital robotic circuits become popular and standard, noise shielding failures can cause sensitive data circuits to be inaccurate resulting in machine failures and miscommunications. Cirrus testers can test these sensitive values repeatedly during assembly to maintain circuit integrity to a high degree.

Incredibly Useful Manufacturing Process Design Tips For All Businesses

In order for manufacturers to maintain profit margins, scalability and repeatability in their processes, critical planning of all the necessary physical components is needed to execute a successful product launch with a client

Custom Build Jigs: Design Techniques Used In The Wire Industry

When a new custom jig is designed, the designer takes into account every connection point possible on the harness in order to plan for integrating real-time high speed test scanning ability into the jig…