Most professional machinery for the commercial wire industry and the tooling options available are shipped with docu….

Wire Cutting & Crimp Die Machine Setups: How To Limit Variability

Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

Quotations: The Basic Requirements For Successful CSA & UL Certified Electrical Cables and Harnesses

It is a known fallacy that different countries around the world use different limits, certifications and safety devices on electrical products that may or may not be legal and certifiable in other regions such as North America where advanced auditing, safety protocols and devices have been created as a result of dangerous products being audited and made safe.

Other certifications sometimes contrast with CSA and UL requirements so machines and devices adhering to other markets need to be readdressed when that product enters the North American Market.

Realizing Value: The Quality Implications Of Using Certified Electronic Components

There are huge cost differences between certified and non-certified components which needs to be considered when engineering a new product

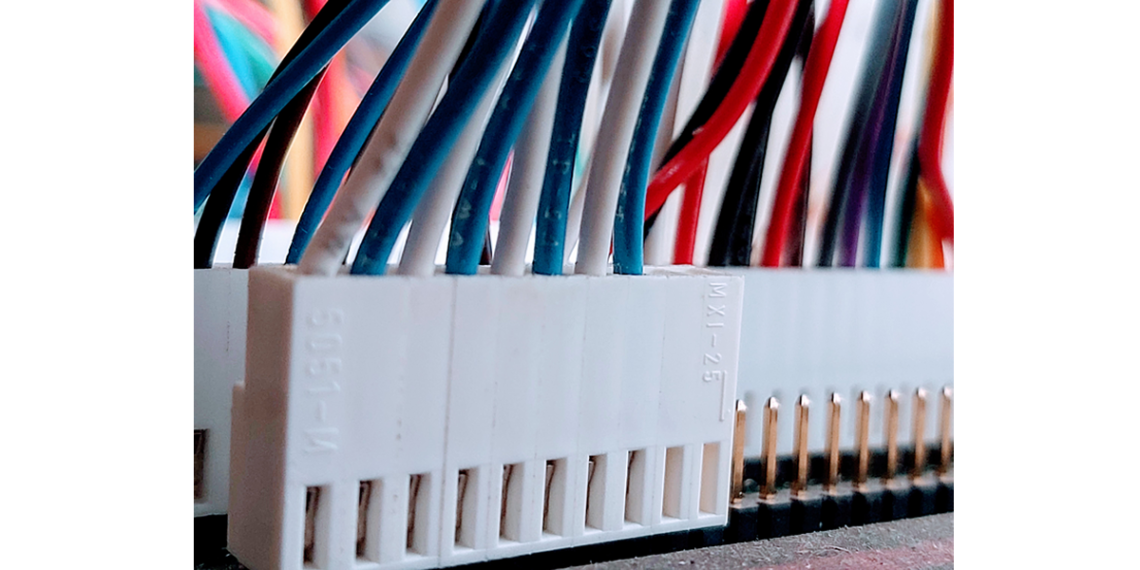

Wire Quality: Common Issues Found During Production

Wire mills around the world each manufacture wire with a variety of requirements and certifications governing their quality. In North America, you will most often see the markings of CSA and/or UL as well as markings specific to industries like automotive and aerospace such as SAE, CE, MIL-XXX etc. depending on application.

Every performance characteristic about a wire is defined within the certifications like maximum operating voltage, flame retardance and burn characteristics, temperature tolerances, insulation thicknesses, platings on conductors.

How To Guarantee Harness Quality: Using Cirris Continuity Scanning

One of the main ways to ensure custom wire harness products are in perfect working order before they leave the facility is to test them against known limits electrically….Especially in low voltage data circuits, small discrepancies in resistance values can cripple digital sensing systems that require tight control of a circuit. As more delicate and complex digital robotic circuits become popular and standard, noise shielding failures can cause sensitive data circuits to be inaccurate resulting in machine failures and miscommunications. Cirrus testers can test these sensitive values repeatedly during assembly to maintain circuit integrity to a high degree.

Incredibly Useful Manufacturing Process Design Tips For All Businesses

In order for manufacturers to maintain profit margins, scalability and repeatability in their processes, critical planning of all the necessary physical components is needed to execute a successful product launch with a client

Aligning Quality Systems For Critical Traceability Of Military and Medical Applications

…They employ advanced tracking/reporting systems and requirements in order to make all parts and components being used in their products traceable….

Custom Build Jigs: Design Techniques Used In The Wire Industry

When a new custom jig is designed, the designer takes into account every connection point possible on the harness in order to plan for integrating real-time high speed test scanning ability into the jig…

Hygroscopic Nylon Parts: A Hidden Quality Lifesaver With Moisture Control

Hygroscopy is described as an objects ability or characteristic to absorb/ give up moisture into its surrounding atmosphere. A great way to think of this is a tree. We all know that trees “suck up” co2 from the atmosphere and release oxygen back into it. Nylon plastic parts do the same with moisture based on the humidity of their environment. Nylon has great thermal and electrical insulating properties but the problem with nylon in professional industries is that it becomes brittle and susceptible to cracking under pressure when it is too dry. Many of the automated processes dealing with manufacturing …

- Page 1 of 2

- 1

- 2