Knowing what the markings mean on registered wire gives you an advantage when dealing with any electrical system. The characteristic information printed on the wire provides a ton of detail about the circuit it is connected to, as well as providing traceability through the supply chain for where the wire came from. These markings define what the wire can be used for, its physical limitations like fire ratings, pliability, compositions, registered file numbers for wire use, wire gauge and more! A telltale sign that you are purchasing registered, high quality wire is that is will always come with printed markings. …

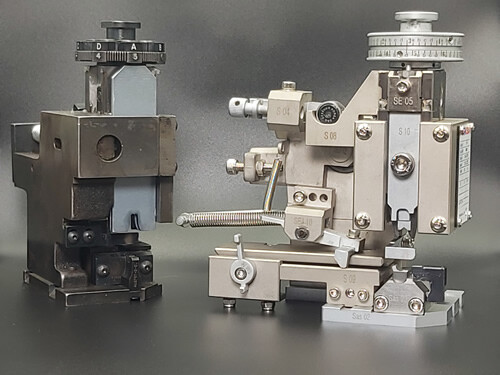

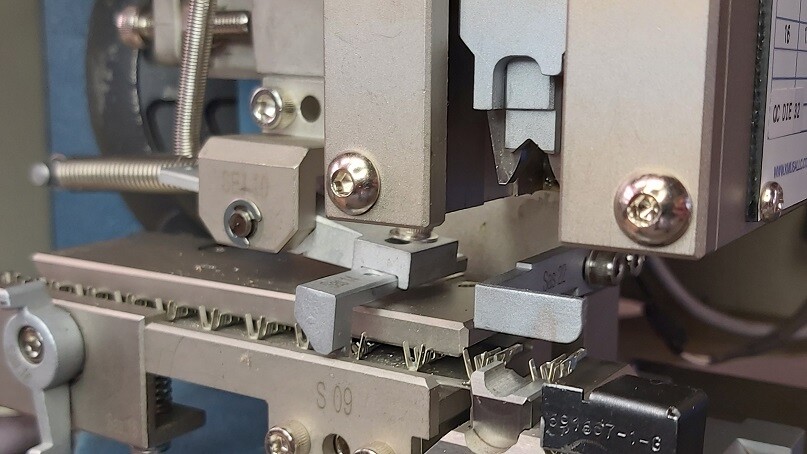

Semi-Automation: High Quality Crimp Tooling For Calculated Results

One of the main challenges that engineers face in the custom wire harness industry is the multitude of different connection systems available on the market. There are literally thousands of different types of connectors and their respective terminals will only fit the matching housings. This poses “pressing” questions (no pun intended!) 1. Which types do any given professional wire harness manufacturing facility have tooling for? 2. Which type are the best? 3. Most cost effective? Part of our job at C-T Wire Prep is to first educate engineering teams responsible for sourcing connection systems for their new products about availability …

Soldering: Techniques for Achieving Strong Solder Connections on Delicate Components

In electronics, Soldering is a semi-permanent process that employs three main components to complete…

Crimp Tooling Choices That Produce High Quality Parts

One of the most important choices you will ever make when sourcing a manufacturing establishment that produces its own cable assemblies or wire harnesses is how they will crimp terminals onto the wires they need. Choosing wisely is based on advanced knowledge of the levels of quality that is achieved using each method available. Smaller companies that are starting out or even larger companies have no formal training in the detailed aspects of wire processing which involves crimping terminals onto wire ends. They usually lean towards the cheapest method. The cheaper method essentially is to use hand-tool type pliers. Below …

Wiring Harness Manufacturing Quality Issues: Adhering To Best Practices

Many business owners, engineers, production managers, and other personnel, who are responsible for the quality and knowledge of their electrical or electronic wire processing, lack the information and training necessary to make sound decisions about quality issues concerning custom wire harness and cable assemblies. When it comes down to it, this information disparity is partly due to the fact that the knowledge, and information necessary to expose the issues involved in wire harness or cable assembly has typically been kept amongst a relatively few individuals inside the industry. People who own, and or at one time or another worked for …

Producing Beautiful Custom Wire Harnesses: Canadian Made Quality

Quality wire harness manufacturing doesn’t happen by accident. Two main quality certifications govern the safety, performance, and repeatability of OEM wire harness and cable products. CSA (Canadian Standards Association) and 2. UL (The Underwriters Lab of America). These certifications guarantee that manufacturers create products using only certified, high quality components produced by reputable companies like TE Connectivity, Panduit, Molex, Amphenol, EDAC, and JST to name a few. The true lifespan of a wire harness is a matter of long term experience building wire harnesses and knowing the intricacies of proper crimping methods, as well as having a wire harness quality …

- Page 2 of 2

- 1

- 2