It takes many years in business to curate a reliable vendor list for raw certified materials. Making orders for materials, seeing the products come in and their quality, lead time analyzation and volume cost breaks all must be top of mind as an outsourcing company to be able to provide a long service life for parts at the best prices.

Wire Cutting & Crimp Die Machine Setups: How To Limit Variability

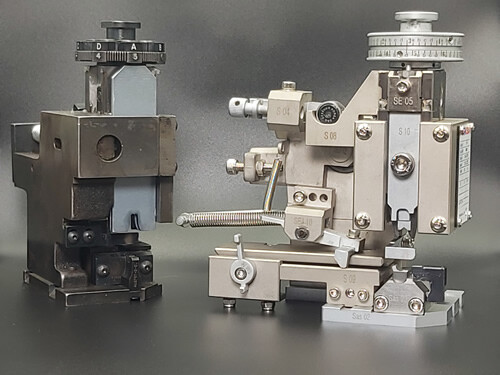

Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

Aligning Quality Systems For Critical Traceability Of Military and Medical Applications

…They employ advanced tracking/reporting systems and requirements in order to make all parts and components being used in their products traceable….

Semi-Automation: High Quality Crimp Tooling For Calculated Results

One of the main challenges that engineers face in the custom wire harness industry is the multitude of different connection systems available on the market. There are literally thousands of different types of connectors and their respective terminals will only fit the matching housings. This poses “pressing” questions (no pun intended!) 1. Which types do any given professional wire harness manufacturing facility have tooling for? 2. Which type are the best? 3. Most cost effective? Part of our job at C-T Wire Prep is to first educate engineering teams responsible for sourcing connection systems for their new products about availability …