The interconnection of multiple digital interfaces enables this new generation of IOT devices that are smart, connected to the internet in real-time and able to communicate both ways from a central IOT management server to machines and back. Machines can be monitored using multiple sources of feedback that allows for all types of data collection and statistics.

How To Find The Right Domestic Manufacturer To Process Electronic Wires

Purchasers and buying agents for electronic product corporations need the secrets – the inside scoop on sourcing vital wire and cable supplies and who to steer clear of

The Role Of Wire Harnesses In The Future Of Electronics

best part about the fly-by-wire method has always been its rock solid reliability. This is why the transition to digital versions has been so slow. Nothing beats the quality levels of the wiring method, but it is too costly to be used for the future…

Machine Maintenance: How To Control The Many Variables In Wire Manufacturing

Most professional machinery for the commercial wire industry and the tooling options available are shipped with docu….

Wire Cutting & Crimp Die Machine Setups: How To Limit Variability

Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

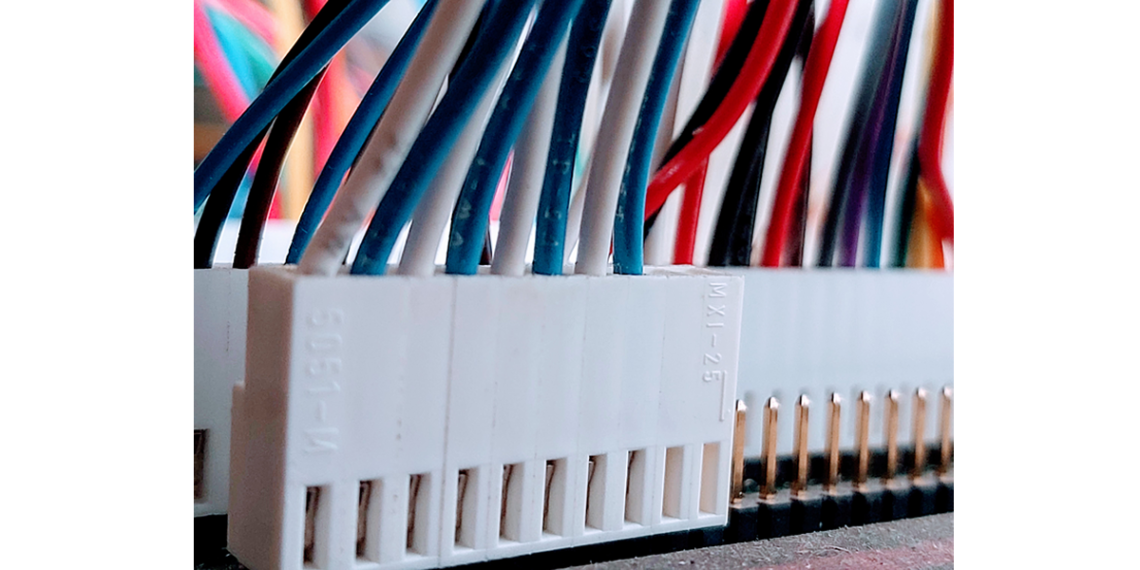

Wire To Wire Connections: How To Perform Commercial Grade Attachments

Electricity does not discriminated on connection quality and will pass voltage so long as there is a physical link of any size from wire to wire. This creates variability in the quality of various connections because of other factors created as a result of less than adequate connection.

Electrical Resistance and Heat are the two main failures created when a wire to wire connection is done wrong…

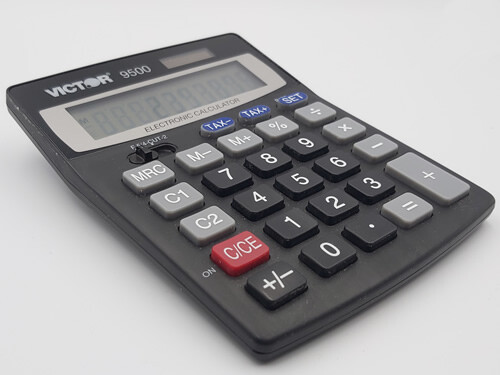

Business Models Are Changing: Taking A more Calculated Approach

The idea of the digital transformation comes as a result of innovating the backbone systems controlling our online experiences. Algorithms dictate much of what we see, how we influence others through marketing, and our overall digital reach as businesses.

If we can learn to understand how these systems work for us, we can best use them for our benefit if we can transform how we do things to excite them.

There are some basic facts about how these algorithms function:

Quotations: The Basic Requirements For Successful CSA & UL Certified Electrical Cables and Harnesses

It is a known fallacy that different countries around the world use different limits, certifications and safety devices on electrical products that may or may not be legal and certifiable in other regions such as North America where advanced auditing, safety protocols and devices have been created as a result of dangerous products being audited and made safe.

Other certifications sometimes contrast with CSA and UL requirements so machines and devices adhering to other markets need to be readdressed when that product enters the North American Market.

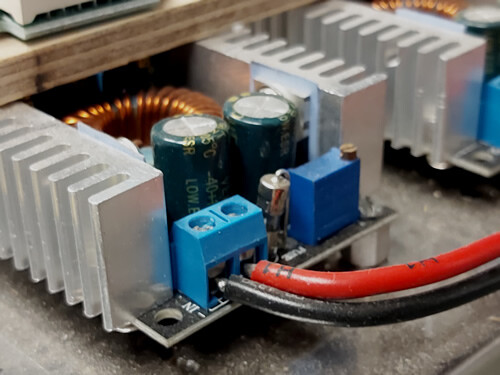

Realizing Value: The Quality Implications Of Using Certified Electronic Components

There are huge cost differences between certified and non-certified components which needs to be considered when engineering a new product

How To Guarantee Harness Quality: Using Cirris Continuity Scanning

One of the main ways to ensure custom wire harness products are in perfect working order before they leave the facility is to test them against known limits electrically….Especially in low voltage data circuits, small discrepancies in resistance values can cripple digital sensing systems that require tight control of a circuit. As more delicate and complex digital robotic circuits become popular and standard, noise shielding failures can cause sensitive data circuits to be inaccurate resulting in machine failures and miscommunications. Cirrus testers can test these sensitive values repeatedly during assembly to maintain circuit integrity to a high degree.

- Page 1 of 2

- 1

- 2