One of the main ways to ensure custom wire harness products are in perfect working order before they leave the facility is to test them against known limits electrically….Especially in low voltage data circuits, small discrepancies in resistance values can cripple digital sensing systems that require tight control of a circuit. As more delicate and complex digital robotic circuits become popular and standard, noise shielding failures can cause sensitive data circuits to be inaccurate resulting in machine failures and miscommunications. Cirrus testers can test these sensitive values repeatedly during assembly to maintain circuit integrity to a high degree.

Fundamentals Of Heatshrink – Discussing The Who, What, Where, When, Why & How

Insulating electrical conductors in discrete circuits has been a necessary process since the inception of electricity. Many studies, developments and innovations in the wire industry have been made regarding thickness, physical characteristics, insulation material types — all with one goal. Safely and effectively insulating the electrical conductors carrying power. Using Heatshrink There are many implications for heatshrink tubing from safety and physcial reinforcement to identifying wire ends. Safety When a wire is stripped to reveal its inside conductors for crimping, soldering or connecting to an electrical system, there is often a need to re-cover the copper to protect the circuit …

Wire Characteristics: How To Read Inkjet Markings On Wire

Knowing what the markings mean on registered wire gives you an advantage when dealing with any electrical system. The characteristic information printed on the wire provides a ton of detail about the circuit it is connected to, as well as providing traceability through the supply chain for where the wire came from. These markings define what the wire can be used for, its physical limitations like fire ratings, pliability, compositions, registered file numbers for wire use, wire gauge and more! A telltale sign that you are purchasing registered, high quality wire is that is will always come with printed markings. …

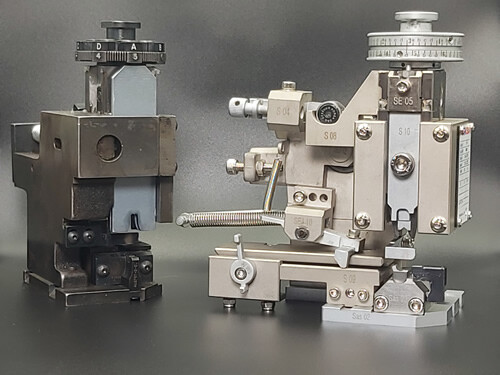

Semi-Automation: High Quality Crimp Tooling For Calculated Results

One of the main challenges that engineers face in the custom wire harness industry is the multitude of different connection systems available on the market. There are literally thousands of different types of connectors and their respective terminals will only fit the matching housings. This poses “pressing” questions (no pun intended!) 1. Which types do any given professional wire harness manufacturing facility have tooling for? 2. Which type are the best? 3. Most cost effective? Part of our job at C-T Wire Prep is to first educate engineering teams responsible for sourcing connection systems for their new products about availability …

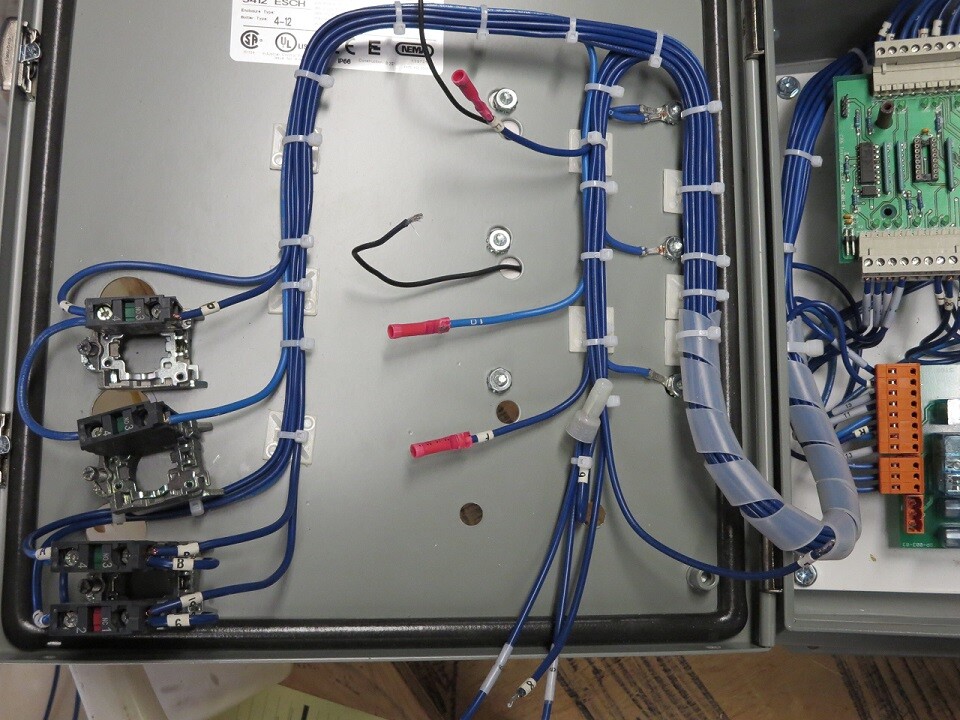

OEM CSA & UL Certified High Volume Simple Lead Wire Producer

C-T wire Prep Inc. has been a long standing player in the OEM electronic lead wire industry as a producer of simple single ended hookup wire for industry. Lead wires are simple wire products that are run at high volume. They include cutting a wire to length and applying a terminal onto one or both ends of the wire. The product is visually inspected and packed directly off the line saving hours of labor which translates into savings for the customer. Lead wire jobs are highly competitive in nature due to their simplicity and the ability to run them on …

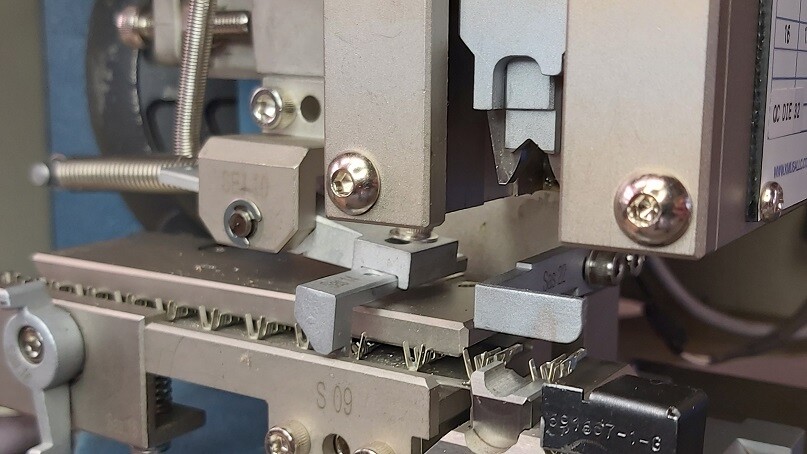

Crimp Tooling Choices That Produce High Quality Parts

One of the most important choices you will ever make when sourcing a manufacturing establishment that produces its own cable assemblies or wire harnesses is how they will crimp terminals onto the wires they need. Choosing wisely is based on advanced knowledge of the levels of quality that is achieved using each method available. Smaller companies that are starting out or even larger companies have no formal training in the detailed aspects of wire processing which involves crimping terminals onto wire ends. They usually lean towards the cheapest method. The cheaper method essentially is to use hand-tool type pliers. Below …

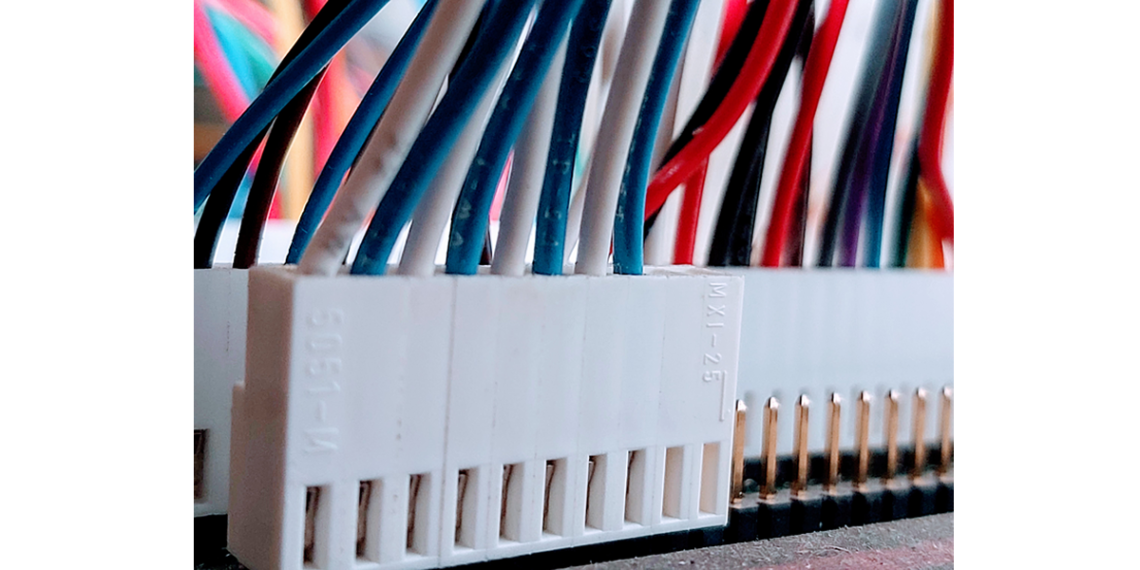

Sourcing Custom Wire Harness Manufacturers: Searching For The Right Supplier

From A Custom Wire Harness Manufacturer As a custom wire harness manufacturer, C-T Wire Prep meets with many individuals each year who are usually employed as purchasing agents or buyers for various OEM’s. Many of these individuals have a limited knowledge scope of the basics about what they are attempting to purchase or find — a regular, repeatable supplier for their custom wire harness or custom cable assemblies. This informative article was put together for the sole purpose of helping out these individuals in their task. So there you are in your purchasing role tasked to find a decent manufacturer …