Purchasers and buying agents for electronic product corporations need the secrets – the inside scoop on sourcing vital wire and cable supplies and who to steer clear of

Wire Cutting & Crimp Die Machine Setups: How To Limit Variability

Having a great setup tech is key to a crimp die operating properly. Every aspect of the material from feeding the terminals into the fixture, positioning, application and cutting off of the terminal from the carrier reel can create variability in the finished product if everything is not aligned, sharp and accurate.

Wire To Wire Connections: How To Perform Commercial Grade Attachments

Electricity does not discriminated on connection quality and will pass voltage so long as there is a physical link of any size from wire to wire. This creates variability in the quality of various connections because of other factors created as a result of less than adequate connection.

Electrical Resistance and Heat are the two main failures created when a wire to wire connection is done wrong…

Quotations: The Basic Requirements For Successful CSA & UL Certified Electrical Cables and Harnesses

It is a known fallacy that different countries around the world use different limits, certifications and safety devices on electrical products that may or may not be legal and certifiable in other regions such as North America where advanced auditing, safety protocols and devices have been created as a result of dangerous products being audited and made safe.

Other certifications sometimes contrast with CSA and UL requirements so machines and devices adhering to other markets need to be readdressed when that product enters the North American Market.

Wire Quality: Common Issues Found During Production

Wire mills around the world each manufacture wire with a variety of requirements and certifications governing their quality. In North America, you will most often see the markings of CSA and/or UL as well as markings specific to industries like automotive and aerospace such as SAE, CE, MIL-XXX etc. depending on application.

Every performance characteristic about a wire is defined within the certifications like maximum operating voltage, flame retardance and burn characteristics, temperature tolerances, insulation thicknesses, platings on conductors.

The Evolution Of Wire Labelling Techniques: Has Quality Improved?

An older method of marking still in use today in many industries, but with caution in the commercial wire industry is Hot Stamping. This method of marking involves some type of heated die and a transfer foil. The foil is placed between the item being…

Hygroscopic Nylon Parts: A Hidden Quality Lifesaver With Moisture Control

Hygroscopy is described as an objects ability or characteristic to absorb/ give up moisture into its surrounding atmosphere. A great way to think of this is a tree. We all know that trees “suck up” co2 from the atmosphere and release oxygen back into it. Nylon plastic parts do the same with moisture based on the humidity of their environment. Nylon has great thermal and electrical insulating properties but the problem with nylon in professional industries is that it becomes brittle and susceptible to cracking under pressure when it is too dry. Many of the automated processes dealing with manufacturing …

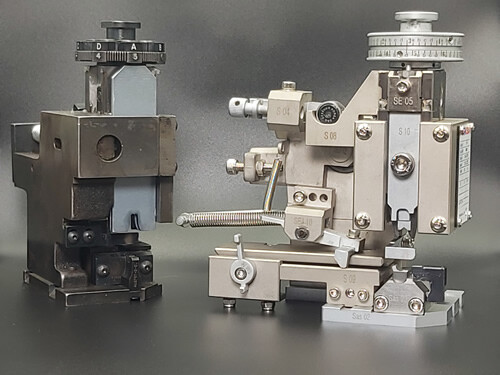

Semi-Automation: High Quality Crimp Tooling For Calculated Results

One of the main challenges that engineers face in the custom wire harness industry is the multitude of different connection systems available on the market. There are literally thousands of different types of connectors and their respective terminals will only fit the matching housings. This poses “pressing” questions (no pun intended!) 1. Which types do any given professional wire harness manufacturing facility have tooling for? 2. Which type are the best? 3. Most cost effective? Part of our job at C-T Wire Prep is to first educate engineering teams responsible for sourcing connection systems for their new products about availability …

Soldering: Techniques for Achieving Strong Solder Connections on Delicate Components

In electronics, Soldering is a semi-permanent process that employs three main components to complete…

OEM CSA & UL Certified High Volume Simple Lead Wire Producer

C-T wire Prep Inc. has been a long standing player in the OEM electronic lead wire industry as a producer of simple single ended hookup wire for industry. Lead wires are simple wire products that are run at high volume. They include cutting a wire to length and applying a terminal onto one or both ends of the wire. The product is visually inspected and packed directly off the line saving hours of labor which translates into savings for the customer. Lead wire jobs are highly competitive in nature due to their simplicity and the ability to run them on …

- Page 1 of 2

- 1

- 2